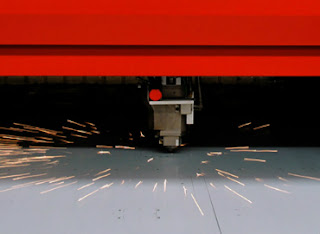

The laser cutting services in Melbourne is known for its manufacturing of process that removes the requirement of machining on engineering and helps you to save money on various manufacturing costs.

One of the professionals who lead such a facility is stainless steel fabricators in Melbourne. They understand the requirement of the customer by studying the blueprint and plan their strategy which they are going to apply in the rest of the task.

The advantage of this process is its non-contact operation. It causes the heating and melting process through heat. It means that the damage to the material is reduced and the cost of repair and maintenance of scheduled parts that were supposed to contact the work surface is avoided.

It offers the smart advantage of low consumption. The cutting machine uses the power of 10KW while the other process takes around 50 KW. It drives production while lowering the cost of energy.

It is a safer method as compared to other cutting processes. It is possible as the beam which used for cutting is sealed in a tight light box.

It works with many different materials such as diamond, plastics, metal, wood, glass, and other materials. It is a quick and efficient method of cutting down in desirable size and creates an intricate and complex shape.

If you require any sheet metal facility, feel free to connect with the leading professional service in your city and areas nearby. You can get in touch through the contact details as provided on the official website. You can also visit in person and specify your requirements.