The main purpose of sheet metal fabrication process is to provide cutting and customising sizes according to client’s preferences. The procedure involves moulding the material in the desired shape before undergoing any process. According to verified portals, techniques like shear stress and electrical discharge machining are utilised for cutting metals into thinner bits.

Why is it Necessary to Consult Experts for Metal Replica Purposes?

One of these operations is sheet metal punching. This is the approach to drill the holes into the plate according to client’s specifications. Skilled manufacturers stated that the process helps to achieve visually pleasing designs on the metal. Furthermore, the process allows the ability to create shapes, assemble parts, and provide number stamping to recognise the product easily.

Professionals are well equipped with advance tools and techniques to automate exact replica while achieving satisfactory outcomes. Additionally, the technique helps to outline all sizes consisting of high and low volume as well as components parts. Skilled manufacturers are highly qualified and experienced enough to resolve complex issues and complete the task within deadline. The procedure saves time and money while reducing the risk of unnecessary expenses.

Generally, many renowned companies highly recommend considering this technique to achieve desired metal shape and improve performance efficiency. Moreover, businesses could utilise this technique to market or promote their products and grab attention of potential consumers.

Benefits of Consulting Professionals for Sheet Metal Services:

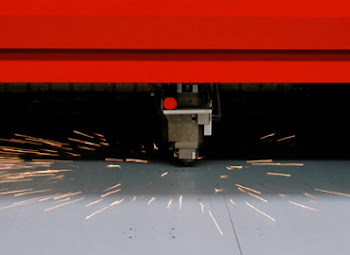

Established companies offer their services that include laser cutting, brake press, fabrication and final assembly depending on client’s requirements. In-addition, they provide effective, fast and safe services to achieve accurate metal dimensions.

- Experts offer screen printing, spray painting, tube bending and other welding services to achieve visually pleasing metal sheet results.

- The code of conduct involves offering customised design options in first go to ensure accurate manufacturing.

If anyone is looking for sheet metal services they should ask for a quote with the best company.