The metal manufacturers in Melbourne are having a great sale in recent years due to a massive shift of people from plastic. Recent research reveals that the components made up of this malleable material release many toxins having carcinogenic impacts on humans. Experts suggest the benefits of using metal boxes and bottles to store food and water. Majority of the companies focus on developing metal products and replacing daily usage equipment made up of the non-biodegradable chemical substances.

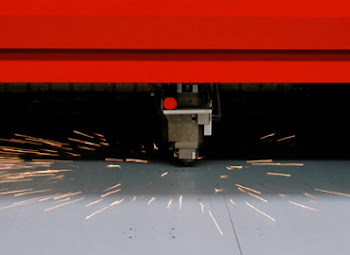

Stainless steel fabricators in Melbourne are using modern techniques to produce suitable quality objects. The usage of SS has significantly increased from myriad industries; people use this raw material to make tableware and cutlery, Cookware equipment like pots, pans, cooking aids, etc., kitchen sinks and kitchen appliances like microwaves, ovens, toasters, etc., garden equipment, furniture, building structures, escalators, etc. The metal structure is given proper shape by welding and fabricating, cutting, burning, forming, machining, to produce equipment.

The products that need superior strength are more resistant to heat, such as weapons, and heavy machinery requires metal as their primary material. The manufacturing companies offer customisation to their customers and use advanced technology to produce objects of convincing quality. Metals are malleable, and people mould them to any shapes and form, therefore many automobile companies consider them the best material to build their parts.

People can ask them to combine two metals to form an alloy that provides better durability than standard metals. Generally, equipment made up of metal can withstand heavy pressure and high temperatures, increasing its durability and longevity over the years. Sheet metals are resistant to corrosion and can resist adverse climatic conditions.

These manufactures modify the metal sheets to form exact parts demanded by the purchaser. They can fabricate the metal sheets according to the requirement of the customer. People can get the desired products in bulk and at an affordable price from the manufacturing company than at the retail stores; the cost of transportation and the benefit of intermediaries is cut down.

The companies have expert workers who have gained several years of experience in this field. Suppose a person is in doubt about the type and size of metal required by them they can consult a fabrication mechanist who will guide them is the best manner. The manufacturing units offer the best quality equipment to their clients, and they give results in significantly less time.