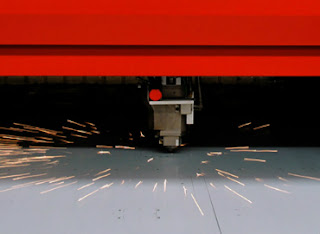

Generally most laser cutting services in Melbourne provide a suite of utilities, ranging from reducing, finishing, engraving, polishing, machining, welding, shearing, metal-forming, rolling, grinding, cladding and also portray and lacquering.

Laser reducing services may be used to manufacture something from sophisticated additives for the scientific and engineering industries, or cladding and ducting for the development industry, to delicately designed jewelry and ornaments, accessories and gildings for architectural functions. With the arrival of advanced CAD systems, repeatability is a general function it truly is offered by means of most laser cutting services for repeat or multiple orders; they can be also sought after for as stainless steel fabricators in Melbourne. These offerings additionally make certain greater green slicing, with minimum wastage of time, cloth and energy assets, with good water-conservation practices for inexperienced compliance.

Large laser slicing companies offer pre-job design consulting, cloth optimization recommendation, venture-sensible consultation for bulk ordering of components, and additionally very last completing services like portray, sprucing or buffing. Since laser presents precise, accurate cutting, the first-class of the finished product is plenty better and there's little or no distortion or warping of surrounding regions. Some corporations specialize in cutting positive substances like carbon, chrome steel, non-ferrous metals into sheets or plates. They can also focus on decorative finishes for architectural functions. Others may additionally consolidate all offerings under a one-prevent umbrella, accordingly ensuring that the client gets fine and consistency in the course of a single activity or for repeat orders.

Depending on character needs, customers need to do an intensive survey of what is available within the area of laser slicing offerings, decide their needs and price range after which make a preference primarily based on a corporation that can provide the maximum accurate, within your means and efficient service.

Internet is one of the best medium to seek services that offers laser cutting and other steel fabrication needs.